Camera lenses achieve zoom by precisely shifting multiple high-grade optical elements along mechanically guided cam shafts and gear trains, altering the focal length within typical ranges of 18–200 mm to vary magnification from wide-angle to telephoto while maintaining image focus through optical compensation systems that stabilize the focal plane. These mechanisms employ low-friction materials and positional linkages to guarantee smooth shifts and minimal distortion, often combined with autofocus motors for independent focusing. Detailed engineering enhances image fidelity and performance comparable to prime lenses, offering versatility for diverse photographic applications. Further technical examination reveals the interplay between mechanical precision and optical design essential for advanced zoom functionality.

Key Takeaways

- Camera lens zoom adjusts focal length by moving multiple lens elements within the optical assembly to change image magnification.

- Gear and cam mechanisms translate rotational input into precise axial shifts of lens groups for smooth focal length variation.

- Lens coatings and optical design maintain image quality by minimizing reflections, chromatic aberrations, and distortion during zooming.

- Mechanical compensation systems synchronize lens elements to preserve focus and sharpness throughout the zoom range.

- Zoom ranges are typically limited (e.g., up to 4x) to balance optical complexity, image fidelity, and mechanical durability.

Basic Components of a Zoom Lens

The basic components of a zoom lens comprise a complex assembly of optical and mechanical elements designed to modify focal length and magnification while preserving image quality. Central to the optical system are multiple lens elements crafted from high-grade optical glass, chosen for its refractive index and minimal dispersion characteristics. These elements, often exceeding thirty in advanced models, include both converging and diverging lenses strategically arranged to enable variable focal lengths. Lens coatings applied to these optical surfaces reduce reflections, enhance light transmission, and mitigate chromatic aberrations, thereby maintaining image fidelity. The mechanical framework integrates precise gear and cam mechanisms, or computer-controlled servos, to facilitate axial movement of lens groups, ensuring consistent focal plane alignment during zoom adjustments. This synergy between optical glass quality, lens coatings, and mechanical precision underpins the zoom lens’s variable magnification capabilities without compromising sharpness. Additionally, the focal length range of a lens significantly influences its versatility across different photography styles.

The Afocal Zoom System Explained

An afocal zoom system constitutes a specialized optical assembly designed to manipulate magnification without altering the convergence or divergence of incident light beams, effectively maintaining collimation throughout the optical path. Such systems achieve magnification control by combining two lens elements separated by a distance equal to the sum of their focal lengths, preserving collimated optics. Afocal applications include telescopes, stereo microscopy, and infrared imaging, where beam expansion or contraction occurs without changing light beam divergence, maintaining image integrity. The magnification factor corresponds to the ratio of focal lengths between optical elements, enabling scalable zoom ranges. This configuration permits seamless integration into optical instruments requiring variable magnification while ensuring minimal aberrations and consistent beam quality, thereby enhancing performance in digital imaging, scientific microscopy, and camera attachment technologies.

Mechanical Mechanisms Behind Zooming

Mechanical assemblies constitute the foundational framework enabling zoom lenses to vary focal length and angle of view dynamically, in contrast to fixed focal length optics. Core components include gear trains and linkage assemblies, which coordinate the axial and rotational displacement of multiple lens groups. Gear trains translate rotational input into controlled linear motion, ensuring non-linear lens element trajectories necessary for precise focal length adjustments. Linkage assemblies, comprising pins and slots, guide these elements with high positional accuracy, minimizing mechanical backlash and maintaining optical alignment. Designs often integrate slide or guide rod transmission mechanisms to optimize compactness and stability. Constructed from industrial-grade materials with matched thermal expansion coefficients, these assemblies maintain calibration under varying environmental conditions. The interplay of gear trains and linkage assemblies underpins focal plane compensation, sustaining image sharpness throughout the zoom range by dynamically adjusting lens spacing and orientation. Additionally, advancements in mechanical design have enhanced the durability and smoothness of zoom mechanisms, leading to more reliable and precise operation over time.

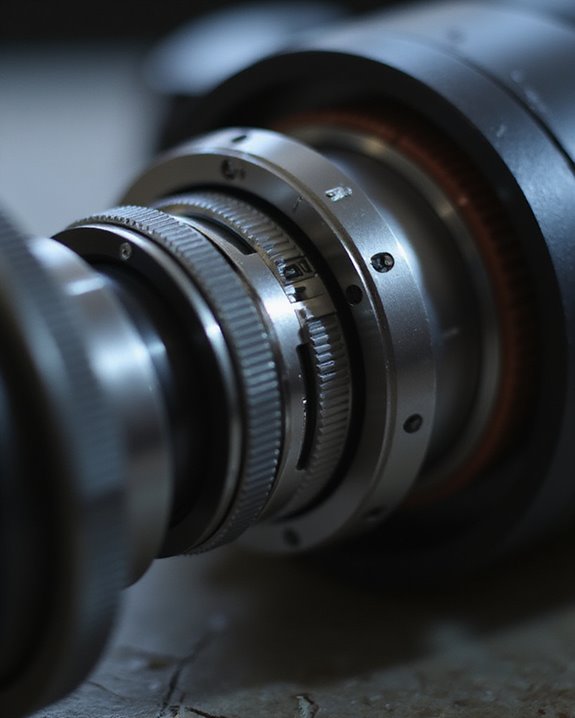

Role of Cam Shafts and Guides in Lens Movement

Cam shafts and guides play a critical role in the precise movement of lens elements within zoom lenses, facilitating controlled axial and rotational displacement essential for focal length variation. The cam shaft, a cylindrically machined component with precision-cut paths, directs lens cells along specific zoom trajectories, while the surrounding cam guide maintains alignment and stability during rotation. Mechanical integration between these parts enables consistent lens positioning, yet cam friction must be carefully managed to avoid jerky or frozen movements. Guide wear, resulting from repeated twisting under load, influences long-term performance, necessitating durable materials and tight manufacturing tolerances. The system’s compact design benefits from optimized mechanical advantage, limiting over-rotation via stop pegs. Consequently, cam shafts and guides constitute a highly engineered subsystem that balances precision, durability, and smooth functionality within complex zoom lens assemblies. Additionally, the use of high-quality replacement parts ensures sustained performance and minimizes wear over time.

How Focusing Mechanisms Work Independently

Focusing mechanisms operate independently from zoom controls by employing dedicated motor systems and mechanical assemblies designed to adjust the position of specific lens elements along the optical axis, thereby achieving precise focus without altering focal length. Phase Detection autofocus utilizes a beam-splitting mirror and dual-image analysis to calculate focus error, directing microprocessor commands to motors such as ultrasonic (USM), stepper (STM), voice coil (VCM), or screw-drive systems for rapid, accurate element displacement. Manual override functionality on many autofocus lenses allows the focus ring to disengage the motor, enabling fine helical focusing adjustments via coarse screw-threads without interrupting autofocus readiness. This separation guarantees that focusing adjustments remain precise and responsive, critical for applications requiring consistent sharpness, while maintaining compatibility across varying motor types and camera body interfaces.

The Function and Importance of Zoom Lock Mechanisms

Zoom lock mechanisms serve a critical role in maintaining the positional integrity of camera lens barrels by preventing unintended extension or retraction during transport and active use. These systems effectively inhibit barrel creep caused by gravity or movement, thereby enhancing shooting stability and protecting internal components from dust and moisture ingress. In outdoor applications, such as hiking or wildlife tracking, zoom locks secure the lens at a set focal length, reducing mechanical wear and improving operational reliability. Storage benefits include securing the lens at its shortest length, minimizing physical stress and potential damage within camera bags. Mechanically, designs range from single-position locks engaging only at wide-angle settings to advanced variable-position systems permitting lock engagement throughout the zoom range, balancing ergonomic handling and environmental hardening in diverse photographic conditions.

Optical Compensation for Constant Focus

Optical compensation mechanisms in camera lenses are engineered to maintain consistent image focus and quality throughout the zoom range, thereby addressing inherent challenges posed by variable focal lengths. These systems employ Constant Magnification Focusing techniques, ensuring focus stability without altering image magnification, which is critical for color image registration accuracy exceeding 99%. Thermal Compensation is integrated to counteract dimensional changes from temperature fluctuations, maintaining sub-micron focus precision across -20°C to 50°C. Digital Integration complements optical adjustments by applying real-time image correction algorithms, enhancing chromatic aberration and shading compensation. While optically corrected zoom lenses typically limit zoom ranges to x4 due to mechanical simplicity, their robust, grease-free design supports durability in harsh environments. Overall, combining mechanical optical compensation with digital methods achieves ideal focus constancy and image fidelity within constrained zoom parameters.

Innovations in Zoom Lens Technology

Innovations in zoom lens technology have greatly advanced optical performance, mechanical design, and digital integration, resulting in lenses capable of delivering superior image fidelity across diverse applications. Meta lenses, employing nanostructured surfaces to manipulate light at subwavelength scales, enable integration with augmented and virtual reality systems while maintaining high resolution and minimal chromatic aberration. Concurrently, periscope tech utilizes folded optical paths with prism assemblies to extend focal lengths within compact smartphone form factors, achieving optical zoom ratios exceeding 10x without increasing device thickness. Multi-lens systems complement these advances, allowing seamless focal length adjustment from wide-angle to telephoto. Collectively, these technologies enhance zoom capabilities, reduce optical distortions, and support smart imaging solutions, thereby expanding the functional range and application scope of modern zoom lenses in consumer electronics and professional imaging equipment.

Precision Engineering in Lens Design

Precision engineering in lens design underpins the ability of advanced zoom systems to achieve superior imaging performance, integrating material science, mechanical fabrication, and optical theory at stringent tolerances. High-grade optical glass, characterized by precise refractive indices and minimal inclusions, is fundamental for reducing chromatic aberrations and maintaining image clarity. The surface finish of each lens element, achieved through meticulous grinding and polishing processes, directly influences light transmission efficiency by minimizing scatter and internal reflections. Mechanical components, often fabricated via CNC machining from aluminum or brass, maintain element alignment within micrometer tolerances. Assembly employs specialized adhesives ensuring long-term stability without compromising optical integrity. Collectively, these factors converge to optimize the optical path, reduce distortion, and enhance overall zoom lens performance, substantiating the critical role of precision engineering in contemporary camera lens design.

Enhancing Performance for Professional Photography

Enhancing zoom lens performance for professional photography necessitates a thorough evaluation of focal length versatility, image sharpness, and mechanical design integrity. Professional-grade zoom lenses integrate complex optical elements and advanced materials to maintain resolution comparable to prime lenses across extensive focal ranges, facilitating dynamic framing without sacrificing clarity. Parfocal designs guarantee subject isolation by preserving focus during focal length adjustments, critical for capturing precise details in sports or wildlife photography. Mechanical compensation mechanisms, supported by computer-controlled servos, stabilize the focal plane to minimize image degradation. Additional technologies, such as optical image stabilization and automatic focus adjustments, further enhance image sharpness and operational efficiency. These combined features empower photographers to achieve seamless shifts in framing and superior subject isolation, essential for high-quality professional output under diverse shooting conditions.

Frequently Asked Questions

How Does Zooming Affect Image Stabilization in Lenses?

Zooming acts like a tightrope walk for lenses, demanding Dynamic Stabilization to balance amplified shakes. Zoom Compensation intensifies, adjusting for narrower views and heavier elements, endeavoring to keep images steady amidst magnified motion and optical challenges.

What Materials Are Commonly Used for Zoom Lens Elements?

Common materials for zoom lens elements include high-quality optical glass, often enhanced with specialized coating types to reduce reflections and aberrations. Entry-level lenses may incorporate plastic elements, while metallic housings provide durability and structural support.

How Does Zoom Speed Impact Video Recording Quality?

A hypothetical wildlife documentary showed that increased zoom speed caused speed artifacts, leading to quality degradation. Rapid zooming stresses bandwidth and processing, resulting in pixelation and motion blur, which reduces the overall clarity and smoothness of video recordings.

Can Zoom Lenses Cause More Chromatic Aberration Than Prime Lenses?

In lens comparison, zoom lenses often cause more chromatic aberration due to complex designs, increasing aberration impact. Prime lenses, with simpler optics, typically exhibit fewer distortions, resulting in sharper images and reduced chromatic aberration effects overall.

How Do Environmental Conditions Affect Zoom Lens Performance?

Amid swirling dust and humid haze, zoom lenses falter; humidity effects invite fungus and corrosion, while temperature variations thicken lubricants and distort optics, blurring images and impairing smooth zoom mechanisms, challenging lens performance in harsh environments.